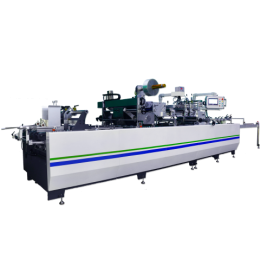

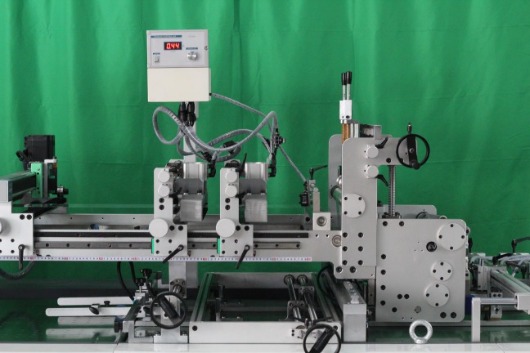

PTW - 760 /1100

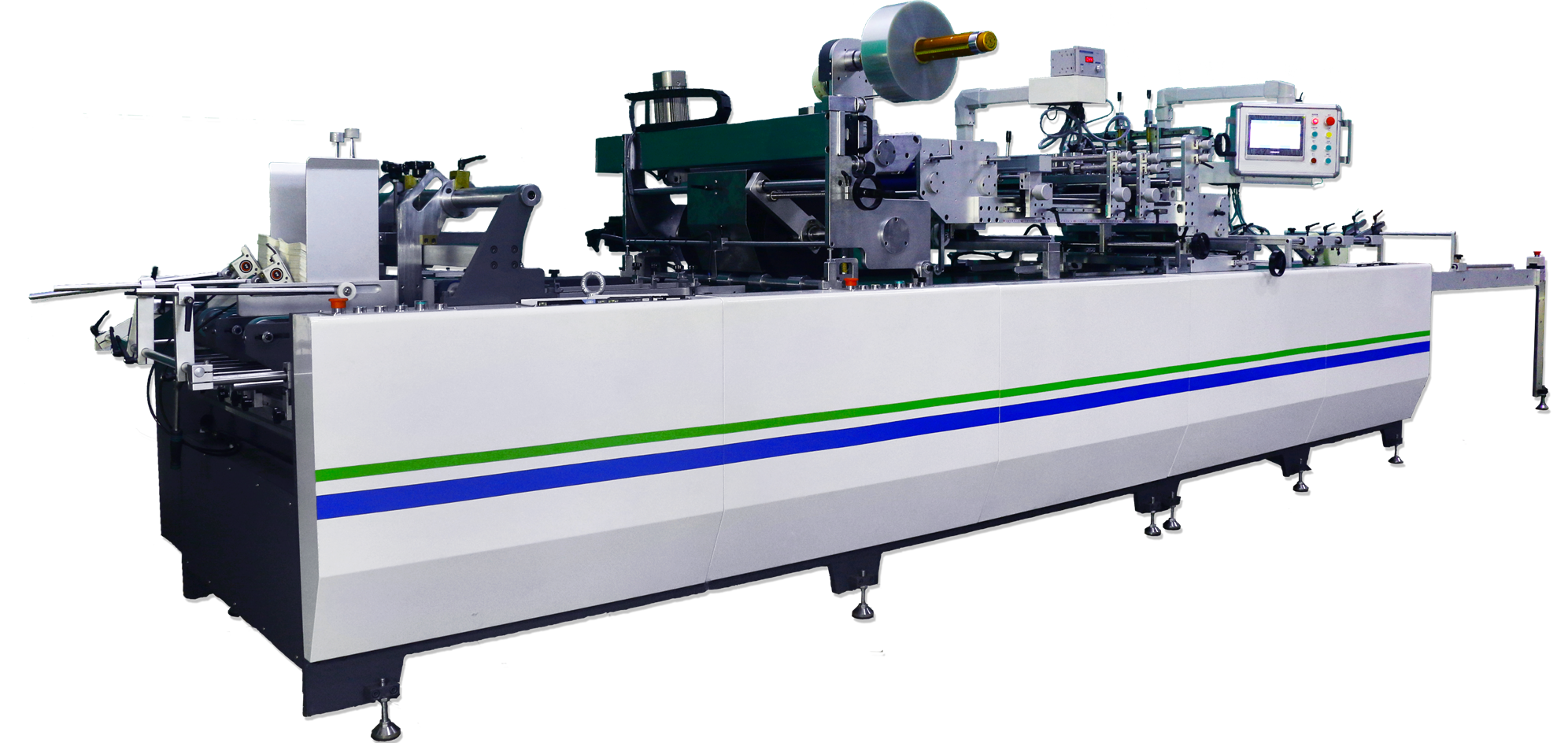

A u t o m a t i c H i g h - S p e e d A n g l e C u t t i n g W i n d o w P a t c h e r

P r o d u c t F e a t u r e s

Accurate, stable and efficient

The PTW series window patcher has the functions of flat pasting and corner cutting. It can accept various PVC films such as PVC, PET, PPOPP material from thickness 0.1-0.35mm.

The machine is fully controlled by servo motors and the align adjustment can be controlled by our unique computer system, it reduces the worker's adjusting time.

Two independent servo motors are equipped in the corner cutting section to ensure no deformation, no stretching, high precision and high stability on the products.

H i g h l i g h t s

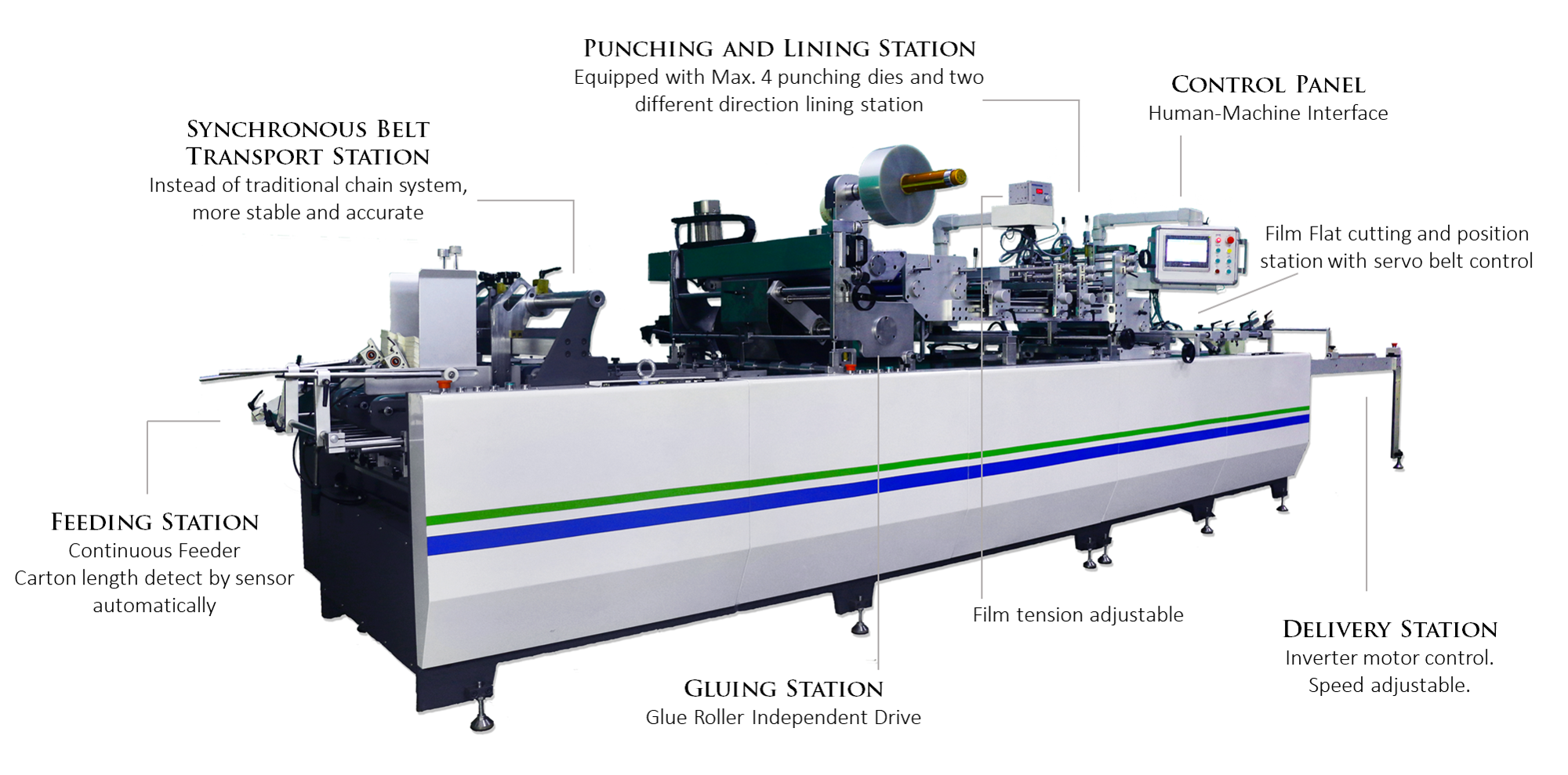

Feeding station

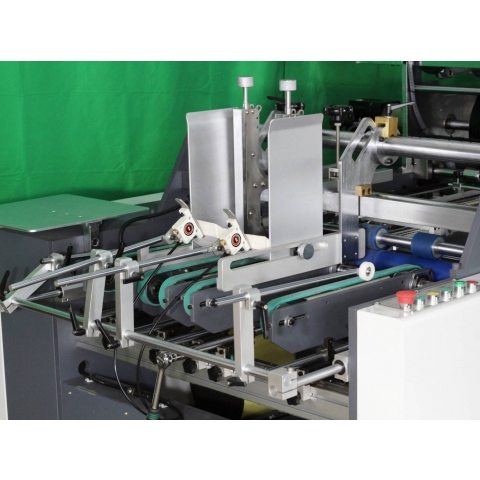

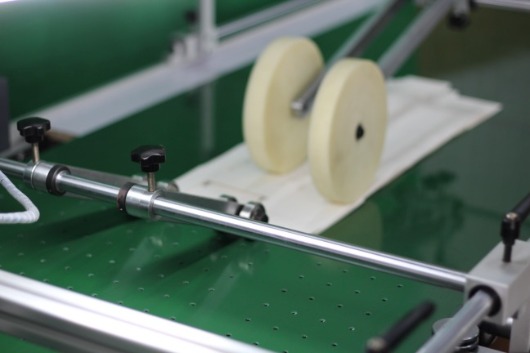

Synchronous Belt Transport Station

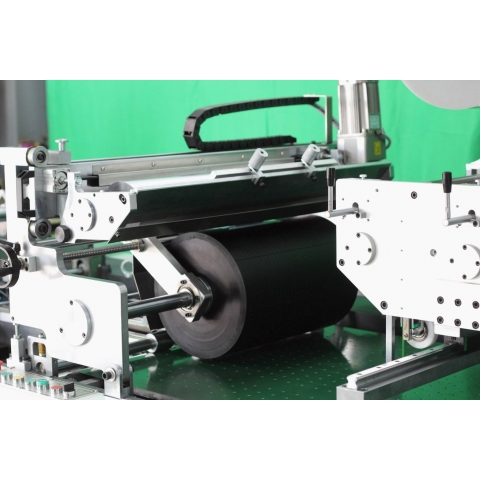

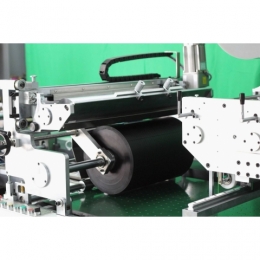

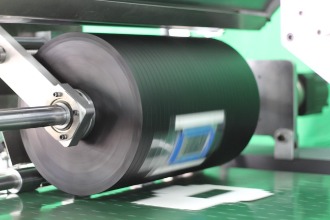

Gluing Station

Punching and Lining Station

Delivery Station

Gluing Station

Control Panel

Machine PLC

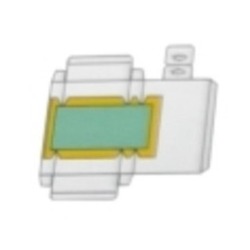

Window Styles

Three creasing lines (Optional)

Double windows paper carton

Double creasing line A

Double creasing line B

General Box

| Performance Characteristic | ||

| Model | PTW-760 | PTW-1100 |

| Paper size | W 760 × L750 mm W 150 × L130 mm |

W 1100 × L750 mm W 150 × L150 mm |

| Paper weight | Cardboard:200-2000 g / m2 Corrugate board:1 – 6 mm |

Cardboard:200-2000 g / m2 Corrugate board:1 – 6 mm |

| Window dimension | W 350 × L300 mm W 50 × L 50 mm |

W 450 × L300 mm W 50 × L 50 mm |

| Film thickness | 0.1 – 0.3 mm | 0.1 – 0.3 mm |

| Positioning accuracy | Top / Bottom:+0.5 mm Left / Right:+ 0.1 mm |

Top / Bottom:+0.5 mm Left / Right:+ 0.1 mm |

| Production speed/Hr | 8000 sheet | 8000 sheet |

| KW / HP | 8.5KW / 11 HP | 12KW / 16 HP |

| Machine. W | 3000 Kg | 4000 Kg |

| Machine. Dia | L7700× W1400 × H1600 mm | L8000× W1700 × H1600 mm |