RW-1200

Ink Roller Washer

The RW-1200 fully automatic ink roller washer is specifically designed for offset printing machines. This design is based on the current problems that printing plants face in terms of time-consuming and troublesome ink roller cleaning. Therefore, this machine is developed to assist printing plants in reducing routine cleaning time of ink rollers, greatly improving print quality, and reducing printing color adjustment time.

H i g h l i g h t s

- The machine can wash ink rollers and water rollers up to B1 paper size.

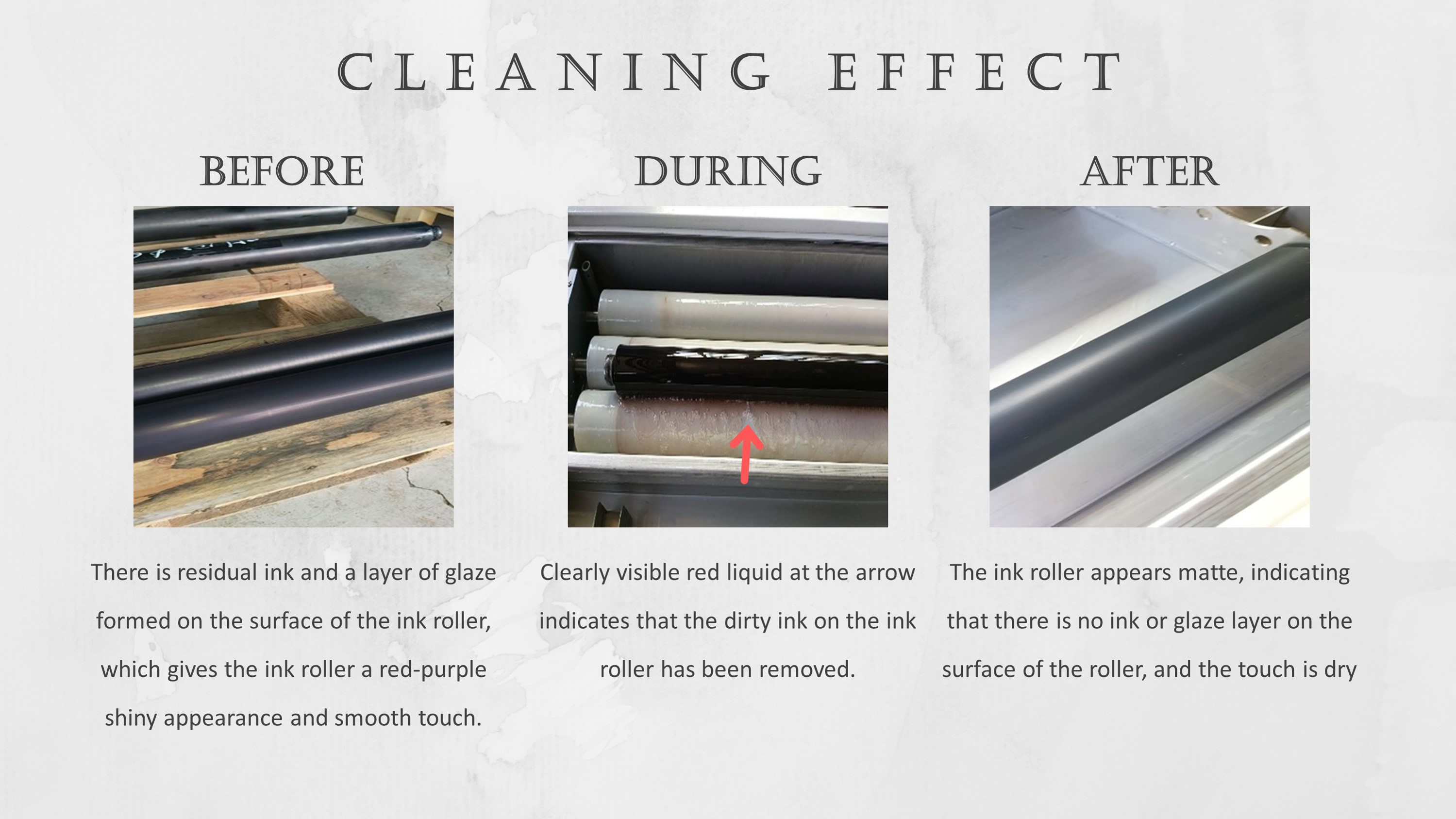

- Using high-efficiency water-based cleaning solution. The machine can quickly and easily remove the glazed or calcified substance on the ink roller surface, resulting in a superior cleaning effect.

- The machine can be operated by one person, time saving and reducing printing machine downtime.

- After cleaning, the roller would be as clean as new one, effectively prolonging their service life.

- The cleaned ink roller has good water-ink balance, which reduces ink emulsification.

- Reduce screentone enlargement.

- It makes the operator much more easier to do color control during new job adjustment.

washing sink / rinsing sink

Manual cleaning V.S. machine cleaning

| Manual cleaning | Machine cleaning | |

| Speed | approx 25 pcs./per person/ day. Low cleaning efficiency. Requiring more manpower for cleaning job. |

Approximately 80~100 pcs/machine/day. Can meet the cleaning needs of thousands of units per month. It has consistent cleaning standards which can significantly reducing printing machine downtime. |

| Effect | Ink and glaze are difficult to clean, and only the surface can be cleaned. | Ink and glaze layer can be easily cleaned, and the effect is significantly better than manual cleaning. |

| Cost | The labor cost is high, additional manpower is required, hard to control emotion of people for doing heavy jobs. | Single investment, long-term benefits, only one to two people can operate the machine. |

| Quality | Manual cleaning can cause uneven cleaning result. Wrong tool could cause ink roller damage. | High-precision roller manufacturing process can uniformly clean the ink roller, maintain the roller roundness , and eliminate concerns about damage caused by improper manual cleaning. |

Specification

| Model | RW-1200 |

| Size of sink | 1,350x650x135mm |

| Time setting range | 1~30min |

| Washing sink capacity | 30L |

| Rinsing sink capacity | 10L |

| Sink quantity | 2 |

| Roller capacity | 2 rollers (can not clean hard rollers) |

| Machine dimension (LWH) | 1,540x850X900 |

| Machine power | 1Ø, 220VAC, 10A |